OEM/ ODM

Production Experience

Plant Area

Production experience

OEM/ODM PROCESS

XINGWEI can provided OEM/ODM service that the components or products produced by our factory are sold under customers’ company's brand, while ODM provides a complete product solution including design, development, production and packaging.

The advantage of OEM/ODM service providers is that they can produce a wide range of products to meet the different needs and specifications of customers. Whether it's a single burner, built-in oven or full gas range, we'll do the job. Customers can customize the size, style and features of gas stoves according to the specific requirements of the markets, including materials, colors, finishes, heat output, ignition types and safety features, etc.

In addition, OEM/ODM service providers have a quality control system to ensure the safety and reliability of products. We have a testing laboratory that simulates different conditions to ensure the products can withstand daily wear and tear and handle any emergencies such as overheating, gas leaks or accidental fires.

By partnering with us, clients can take advantage of these advantages and achieve their business goals.

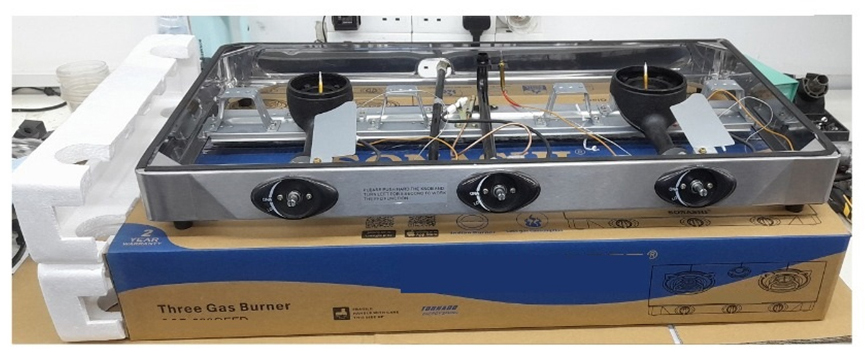

CKD Order

The term CKD stands for “Completely Knocked-Down”. It is another type of manufacturing process adopted in the product manufacturing field. In this process, the manufacturer completely strips down or disassembles a product at the origin and reassembles it in another country.

CKD (Completely Knocked Down) and SKD (Semi Knocked Down) refer to the process by which parts and components of a product are shipped to the assembly plant, where they are put together to create the final product. In the case of gas cookers and ranges, the components would be things like the burners, knobs, grates, and more

①

②

③

One of the main advantages of using CKD/SKD for gas cookers is that it reduces the amount of time it takes to assemble a finished product. With CKD, all the parts and components are packaged in one box and delivered to the plant where they are assembled on-site. With SKD, some parts are assembled before they are shipped and others are assembled on-site.

Another advantage of CKD/SKD for gas cookers is that it reduces shipping costs. Since the components can be packaged more efficiently than the finished product, more of them can be shipped in one container. This can also reduce the risk of damage during shipping.

In addition to these benefits, CKD/SKD for gas cookers can also make it easier to customize products for different markets. For example, if a manufacturer wants to sell gas cookers in different regions with different regulations or requirements, they can easily adjust the components according to each market's needs.